TTCPS-001

TTCP SENSOR

Determining

alignment/

misalignment

of torch

alignment/

misalignment

of torch

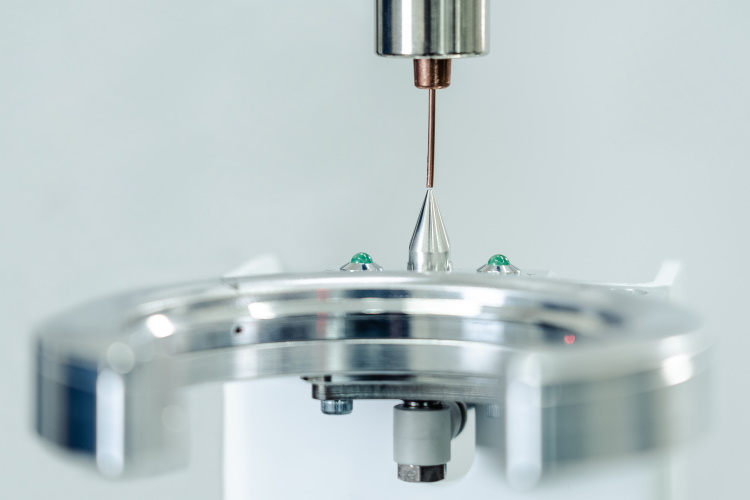

The TTCP Sensor allows you accurately quantify torch misalignment.

Improve your production efficiency and stability even further by using the TTCP Sensor in conjunction with our other products.

Improve your production efficiency and stability even further by using the TTCP Sensor in conjunction with our other products.

TTCPS-001

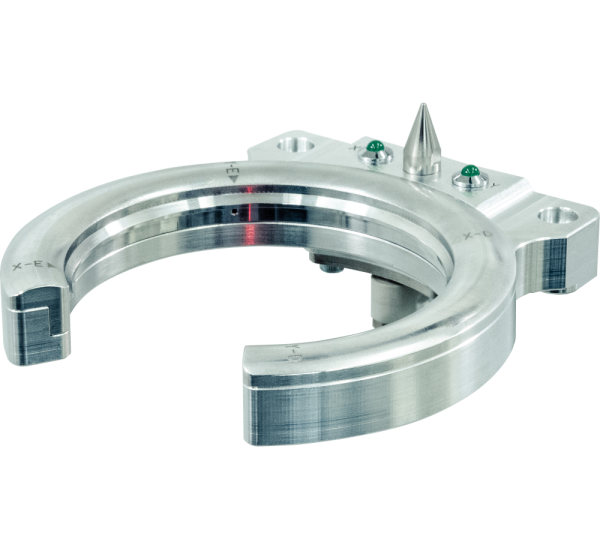

TTCP Sensor

Outline

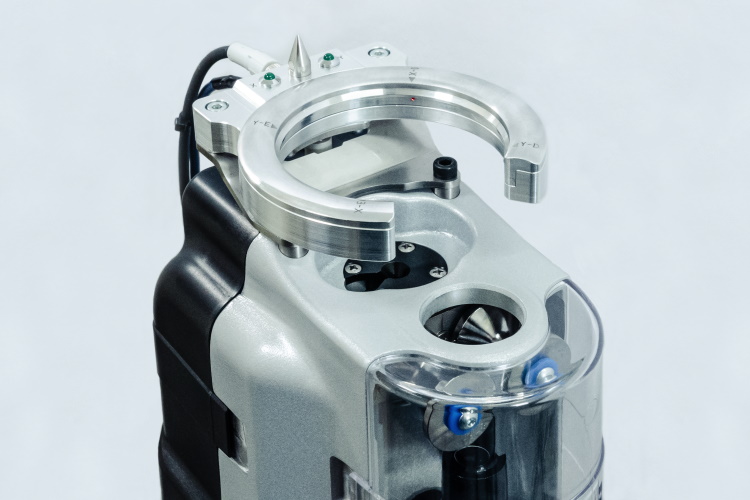

The TTCP Sensor delivers quality welding, stability and efficiency to your production.

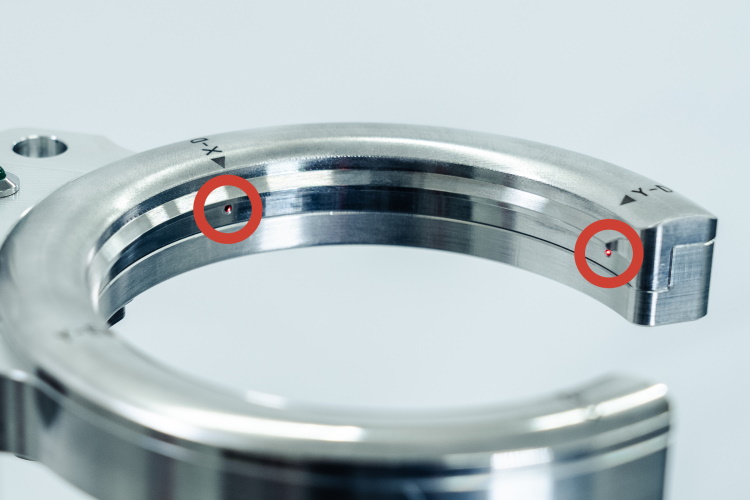

– Two sensors help quantify torch misalignment

– Installed with a dedicated circuit board to ensure accurate calculations

– Scan history stored in the on-board memory can be used for analyzing previous alignment data

Specification

| Model | TTCPS-001 |

|---|---|

| Power | 24VDC 0.2A |

01

Registering the two base alignment points to the controller.

02

[How to register base alignment points]

1. Press “RST” to reset the alignment values

2. Press “SET” to set the base alignment points

3. Check that the controller shows “0” after robot operations

1. Press “RST” to reset the alignment values

2. Press “SET” to set the base alignment points

3. Check that the controller shows “0” after robot operations

03

Cleaning the TTCP sensor of dust by blowing it with air to reduce chances of sensor errors.

04

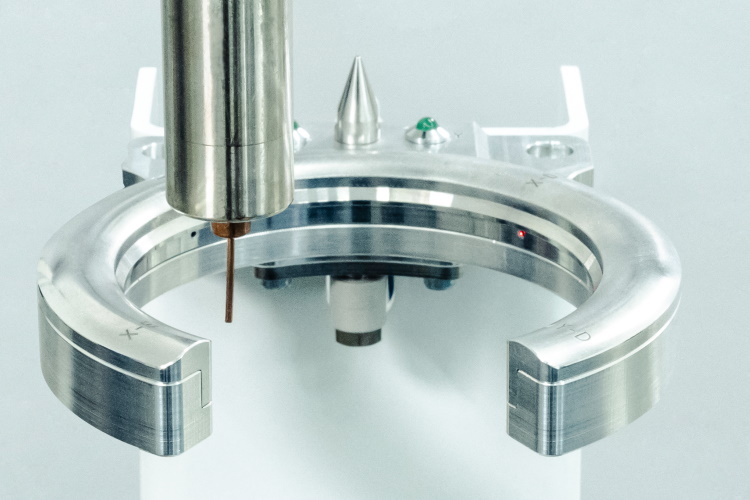

The X : Y : Z axis of the torch is scanned by the two sensors which measure torch misalignment.

05

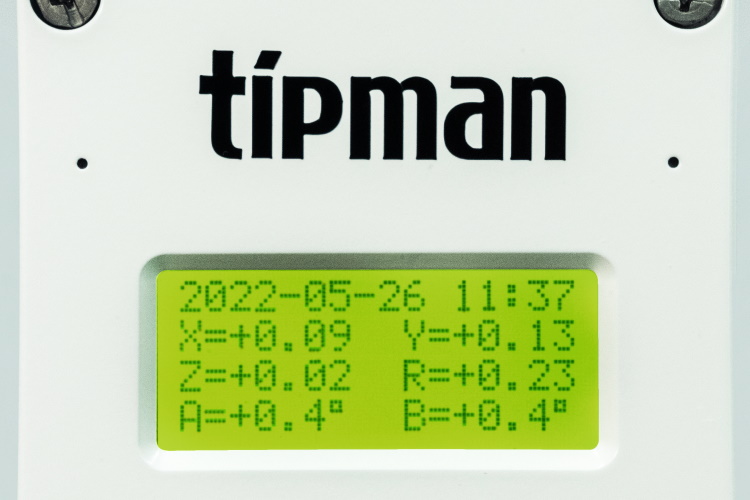

Scanned values are displayed on the controller.

If the scanned alignment values exceed the set base alignment points, an error message is sent to a compatible device of your choice (such as warning lights, buzzers, robot controllers and other devices).

If the scanned alignment values exceed the set base alignment points, an error message is sent to a compatible device of your choice (such as warning lights, buzzers, robot controllers and other devices).

06

Make the necessary readjustments after checking the alignment values displayed on the controller.

07

Scanned values are stored in the on-board memory.

History of the scanned values can be checked by pressing the “History button”.

History of the scanned values can be checked by pressing the “History button”.

08

The TTCP Sensor can be attached to other TIPMAN products or to its dedicated stand.

OPTIONAL

STAND

RELATED

CTC-001

CTC-001