NCOP-SP03

SPRAY

SYSTEM

SYSTEM

Applying an

appropriate

amount

appropriate

amount

The Spray System can be installed very easily, as it does not require an I/O connection with the robots in use.

It helps to improve weld quality by applying an appropriate amount of spray.

It helps to improve weld quality by applying an appropriate amount of spray.

NCOP-SP03

Spray System

Outline

We have developed a spatter deposition prevention spray system that is very easy to install, as it does not require an I/O connection with the robots in use.

The amount of spray can be adjusted with a valve, and further fine-tuning is possible by adjusting the the amount of time the nozzle is pressed down.

The excess liquid is collected, which keeps it from contaminating the workplace.

It contributes to improve weld quality by maintaining nozzles at a consistent quality at all times without stopping production lines.

The amount of spray can be adjusted with a valve, and further fine-tuning is possible by adjusting the the amount of time the nozzle is pressed down.

The excess liquid is collected, which keeps it from contaminating the workplace.

It contributes to improve weld quality by maintaining nozzles at a consistent quality at all times without stopping production lines.

Specification

| Model | NCOP-SP03 |

|---|---|

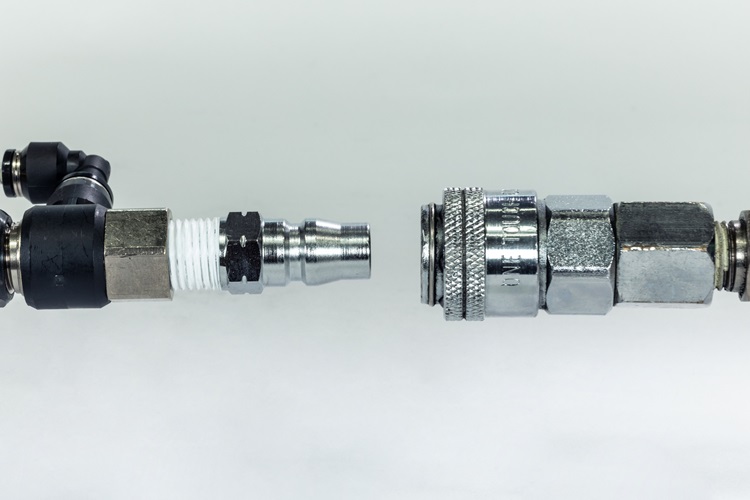

| Air pressure | 5kgf/cm² |

| Air hose diameter | Inside diameter of φ4 mm or more |

| Air hose | for sputter |

| Spray solution | Spatter Adhesion Preventive Agent |

| Weight | 2.3kg |

01

To install it, the only input required is a pneumatic hose. Communication with the robots in use is unnecessary.

02

The welding wire is retracted, and the nozzle is inserted into the holder.

03

The nozzle is pressed down on the device, and it is sprayed with an anti-spatter liquid. Spray is evenly applied to the inside of the nozzle.

04

The amount of spray can be adjusted to prevent the anti-spatter liquid from going to waste. The excess liquid can also be recovered and reused.

05

The nozzle is pulled back up and spraying is complete.

OPTIONAL

STAND

RELATED

NCAM-04

NCAM-04